production

Research and design of fittings for braking systems

We are constantly searching for alternative materials for the production of our fittings, also on the grounds of customers’ demands, through design with the help of the computerized program CAD 3D. Every new designed product is prototyped and monitorized during the production phase and then tested according to norms Iveco Standard 18-2715 to respect the specifications required by TÜV.

Production and control

The produced parts are carried out starting from bar and from forged part with high technology machinery, operated by specialized technicians, giving top production capability supported by an efficient and systematic quality control through SPC and according to norm UNI EN ISO 9001:2000 and technical specification ISO TS 16949.

Washing

At the end of the production cycle, parts are washed through washing machine with vacuum technology with solvent and modified alcohol with zero emission in the atmosphere.

superficial treatments

On customers' request we can carry out thermal (in our company) or galvanic (external) treatments.

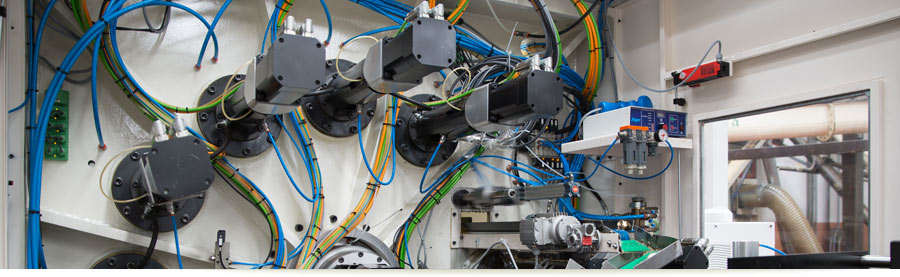

assembling

Then the push-in fittings are automatically assembled and tested in machine through modern equipment that sense the presence of the components, their correct assembling, the pressure seal and fitting force to insert the tube.

Testing

The completed fittings are then tested 100% again by skilled workers, stamped with the specifications of the tube to insert and the necessary data for traceability.