assembly instructions

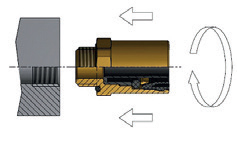

STRAIGHT TERMINAL ASSEMBLY

Screw the joint on the female threading seat. For a correct assembly of each joint follow the tightening coupling instructions given in table 1.

| THREAD | TIGHTENINGTORQUE (Nm) ± 10 |

|---|---|

| M 10 X 1 | 22 |

| M 12 X 1,5 | 24 |

| M 14 X 1,5 | 30 |

| M 16 X 1,5 | 35 |

| M 18 X 1,5 | 36 |

| M 22 X 1,5 | 40 |

| M 26 X 1,5 | 45 |

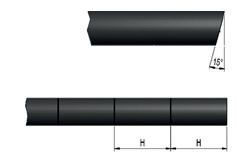

The pipe must be cut at a right angle or up to a maximum

of 15°. The coupling is correct only when the pipe reaches

the coupling value given in table 2.

If the pipe bears a

reference mark it must be cut exactly at that point.

| ØPIPE | DEPTH OF COUPLING (H) |

|---|---|

| 6 X 4 | 19,8 |

| 8 X 6 | 20,5 |

| 10 X 7 | 24 |

| 10 X 7,5 | 24 |

| 10 X 8 | 24 |

| 12 X 9 | 25 |

| 15 X 12 | 27 |

| 16 X 12 | 27 |

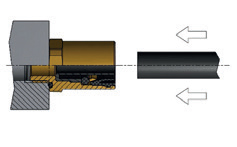

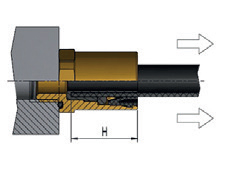

Insert the pipe into the joint rotating it slightly to ease the

insertion.

The pressure required to insert the pipe is given in table 3.

| Ø PIPE | FITTING FORCE (H) |

|---|---|

| 6 | 60 |

| 8 | 80 |

| 10 | 82 |

| 12 | 95 |

| 15 | 100 |

| 16 | 100 |

| 18 | 100 |

If there is a reference mark make sure the cut is flush with the joint. Pull on the pipe to make sure it is correctly fitted in.